Pipe insulation | Mineral wool, plastic or rubber?

Christin Busch Reading time approx. 6 minutes

Which pipe insulation for which purpose?

When building a new house or renovating an old one, heating pipes need to be insulated. The right pipe insulation can sometimes drastically reduce energy costs in the house and also complies with the current insulation regulations of the Energy Saving Ordinance (EnEV), which specifies the thermal conductivity.

Installer insulating heating pipes, picture: Isotec GmbH

Which pipe insulation is the right one is usually decided by three points:

- Fire protection

- Temperature resistance

- Price

Advantages of good pipe insulation

Heating and hot water pipes need protection from cooling down, especially in winter. Poorly insulated pipes not only waste valuable resources, but it also takes much longer for heat to reach the inside of the house/flat. Pipe insulation can reduce heat loss by up to 70 percent.

In the summer months, on the other hand, cold water pipes create a risk of sweating and, when heated, they can even provide a habitat for legionella. Legionella bacteria can get into the drinking water pipes via the central water supply and thus cause pneumonia in about 10,000 people/year. Professional pipe insulation that prevents condensation can prevent this.

Pipes must be insulated in accordance with the EnEV specifications. This standardises the properties of the insulation, to which all manufacturers must adhere. The pipe to be insulated is a suitable yardstick for determining how thick the insulation must be: the insulation material should be about as thick as the pipe. In addition, EnEV markings on the insulation material help to identify the correct pipe insulation.

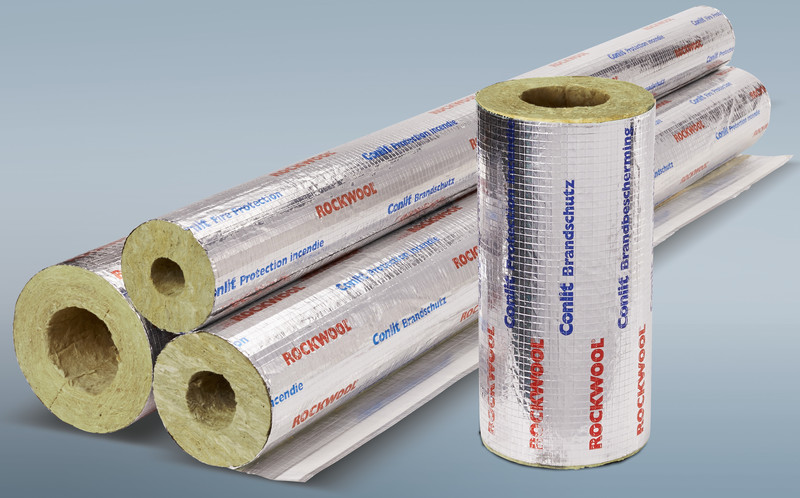

Conlit 150 U fire protection pipe insulation made of rock wool, photo: Rockwool

Best-seller mineral wool: a stable and non-combustible pipe insulation

Pipe insulation made of mineral wool is very suitable for heat-carrying pipes: the wool is pressed into a pipe shape and then covered with aluminium. As with plastic insulation (see below), the tubes are not flexible and therefore cannot be installed everywhere.

When insulating with mineral wool, you should always wear skin protection, as the insulation material can cause severe itching.

Pipe insulation made of mineral wool is not flammable and can withstand high temperatures of up to 250 degrees Celsius. This makes mineral wool suitable as an insulation material for solar systems and (multi-family) houses.

It is true that the cost of raw insulation made of mineral wool is somewhat higher than insulation made of plastic. However, the significantly better quality is convincing, as the insulation material is extremely heat-resistant and non-combustible.

Plastic insulation: cheap but with limitations

Plastic insulation, also called polyethylene (PE) or polyurethane (PUR), is the cheapest material for pipe insulation. The cheap alternative has one major disadvantage. However, it is not resistant to high temperatures and is therefore unsuitable for some pipes. Solar pipes, for example, get particularly hot at up to 160 degrees Celsius and therefore cannot be insulated.

Plastic pipe insulation is most commonly used when the pipelines are easily accessible and not in the high-temperature range. The tubes are usually sold per metre. These are prefabricated with slits and have a self-adhesive foil. This means that the hose only has to be slipped over the pipe and sealed with the protective film.

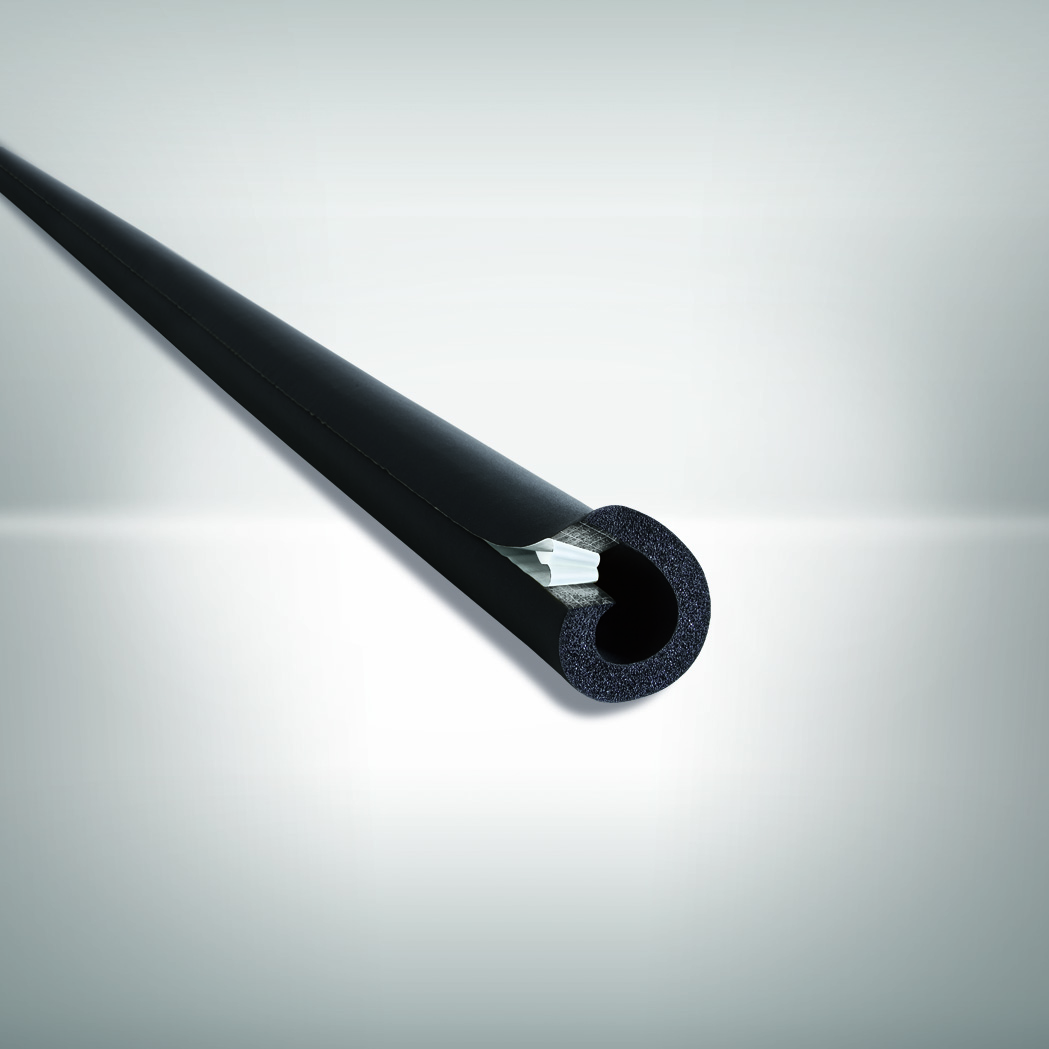

For insulation systems where access is more complicated, rubber insulation is much more suitable because it is flexible in shape.

Slotted rubber pipe insulation, picture: Armacell

Flexible and hard-wearing: pipe insulation made of rubber

Somewhat more expensive in price, pipe insulation made of rubber offers several advantages: The closed-cell synthetic rubber compound is very flexible and therefore particularly suitable for angled insulation systems, corners and turns. In addition, rubber insulation is flame-retardant, so it can also be used to insulate solar lines. Rubber pipe insulation such as Armaflex AF has an additional antimicrobial Microban® protection that prevents condensation. This makes it suitable for use in public buildings and process plants.

Which pipe insulation should I choose?

Know the intended use before you buy

Above we have listed the properties of the different materials. When deciding between mineral wool, plastic or rubber, however, the intended use is the most important factor.

Rubber insulation is usually designed for different temperature ranges, such as for heating, solar systems and refrigeration or air conditioning systems. While rubber in the normal temperature range is used for heating systems, solar cables require a temperature resistance of up to 175°C. Air-conditioning systems, on the other hand, require a very low application temperature of down to -30°C. The intended use must therefore be considered before the insulation is purchased.

insulated and clad heating system, picture: Isotec GmbH

Calculate pipe insulation correctly

You should know the pipe diameters and the total length of all pipes to be insulated so that you can calculate accordingly. Also consider the distances between the pipes: If you calculate too little space between two pipes, the pipe insulation may not fit.

Valves, fittings and other openings should be enclosed as much as possible, as you will only achieve maximum energy efficiency if there are no gaps in the insulation. In addition, transitions should then be sealed with insulating tape to avoid cold bridges.